Recrystallization is a technique which is used to purify a solid substance from a mixture of impurities by dissolving it in the appropriate solvent and recrystallising it. The method is largely based on the differing solubility of the substance and its impurities. Recrystallization is applied in the salt purification process to remove unwanted impurities, where the aim is to obtain the highest possible concentration of sodium chloride (NaCl) while minimizing impurities as far as possible.

Salt in nature exists either in crystalline deposits (mineral salt, solar salt) or in dissolved form (sea water, salt lakes, natural brine). Depending on the source of the salt, the concentration of natural impurities it contains, varies. There are two categories of impurities.

- Surface impurities, such as small amounts of soluble components (mainly Mg, Ca, K salts, etc.) and insoluble components such as sand and clay, which exist on the surface of the salt crystal structure, sometimes in high concentrations.

- Intra-crystalline impurities, which are the result of the uncontrolled crystallization process and include both soluble and insoluble components within the NaCl (sodium chloride) structure.

Impurities of the first category can be removed to a certain extent by mechanical processes (salt washing, etc.). Intra-crystalline impurities, however, can only be eliminated by dissolution and recrystallization of the salt.

The process of salt recrystallization

The basic process used to produce high quality pure salt is the so-called vacuum evaporation crystallization. During this process the thermodynamic equilibrium of solubility in a saturated saline liquid is disturbed, resulting in the production of particles. The solutes eventually precipitate off the liquid as solid crystals with a high degree of purity.

The process involves brine generation usually through solution mining techniques followed by pumping to the main salt plant. Once the brine is pumped to the main plant, it undergoes a multi-stage purification process through a series of tanks and reaction vessels where the necessary chemicals are added to remove the salts, mainly magnesium and calcium. The solution is then filtered and transferred to the final brine tank.

From there, the saturated brine is fed into an evaporation unit where crystallization takes place. As the brine is heated in the vacuum chamber, the water molecules begin to evaporate and escape from the solution, leaving a salt slurry. This salt slurry goes through a series of treatments such as centrifugation, drying and sieving to separate the salt crystals according to their particle size and form the respective products.

Derivatives from recrystallization and basic applications.

Recrystallization is highly useful for the production of high purity salt for applications where the purity and the particular shape of the salt is crucial.

PDV

Vacuum salt, PDV, is a stable quality brine product produced in factories in Europe. Its applications span from the food industry to numerous other industries and it comes with a number of certifications for the relevant uses.

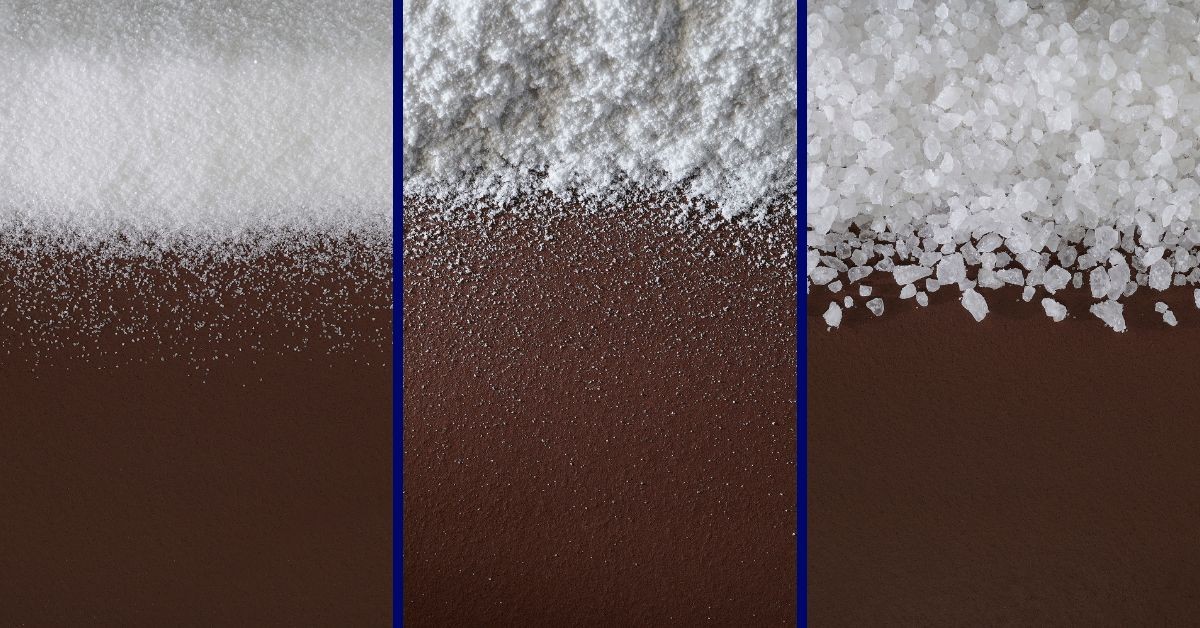

It is of high purity and is mainly available in two different particle sizes: fine (0,1 to 0,7 mm) and coarse (1 to 3 mm).

PDV salt with the same purity is available in the following forms:

with various percentages of sodium nitrite, ready for use in the meat industry

with a lower percentage of sodium and added potassium

with very low particle size (extra fine)

with added iodine in different proportions

Tablets of recrystallized salt

Produced from recrystallized table salt, they are certified and have a certain design that makes them unique. This is a novelty with significant advantages, ideal for areas where water contains high levels of calcium and/or magnesium salts, which hampers the operation and efficiency of hydraulic systems.

AXAL® Pro or Regenit recrystallized salt tablets consist of high purity vacuum salt with a sodium chloride content of at least 99.8%, effectively preventing salt deposits in water softeners. Their patented, convex shape and low particle content help to ensure better dissolution.

Their main benefits include rapid dissolution without residues and the contribution to the maintenance of water softeners (through optimal operation of the ion exchanger system).

They are mainly used in the hotel and catering industry (HO.RE.CA.), professional laundries and industrial cleaning.

In conclusion, salt recrystallization is a fundamental process from which high purity salt crystals of controlled size and morphology are obtained. The derived salt crystals have numerous applications in the modern industry and benefits that we enjoy in our daily life.